- C#

- .NET

- OpenGL

- 3D

- 2D

“From idea to virtual prototype in 5 minutes!”

Accessorize3D is a desktop application that allows you to create a 3D virtual prototype of a button in no time.

Traditional prototyping involves phone calls to exchange information between the designer and the button manufacturer, followed by the creation of a physical prototype and sending the sample to the designer. This process, often slow and cumbersome, frequently fails due to misunderstandings or simply because the sample does not meet the designer’s expectations.

Thanks to Accessorize3D, just a few minutes after the request, the designer is able to evaluate with good accuracy the product they will receive. Since the application field is fashion, a physical sample will still be necessary to test on the final garment, but this physical prototype will be created with a higher level of awareness and with a higher chance of being accepted, precisely because it has already passed a first virtual test.

The process created with Accessorize3D by Intré can also be applied to other products and markets. Maybe even yours?

Here’s a brief spot about the product.

Simplicity, accuracy, and speed

The main objectives we set when developing this product were essentially three: iin a short amount of time, a user o 3D drawing expertise should be able to create an accurate prototype.

We then designed an intuitive interface, with both 2D and 3D views visible simultaneously, and organized the commands so that each software option can be reached with just one click.

We implemented the operations and graphic objects used in the button industry: front and back processing; engraving and carving of radial, linear, and cylindrical text; engraving and carving of logos; application of shanks.

To make the button more realistic, its surface can be colored or covered with special effects.

This 6-minute video illustrates the main features of the software.

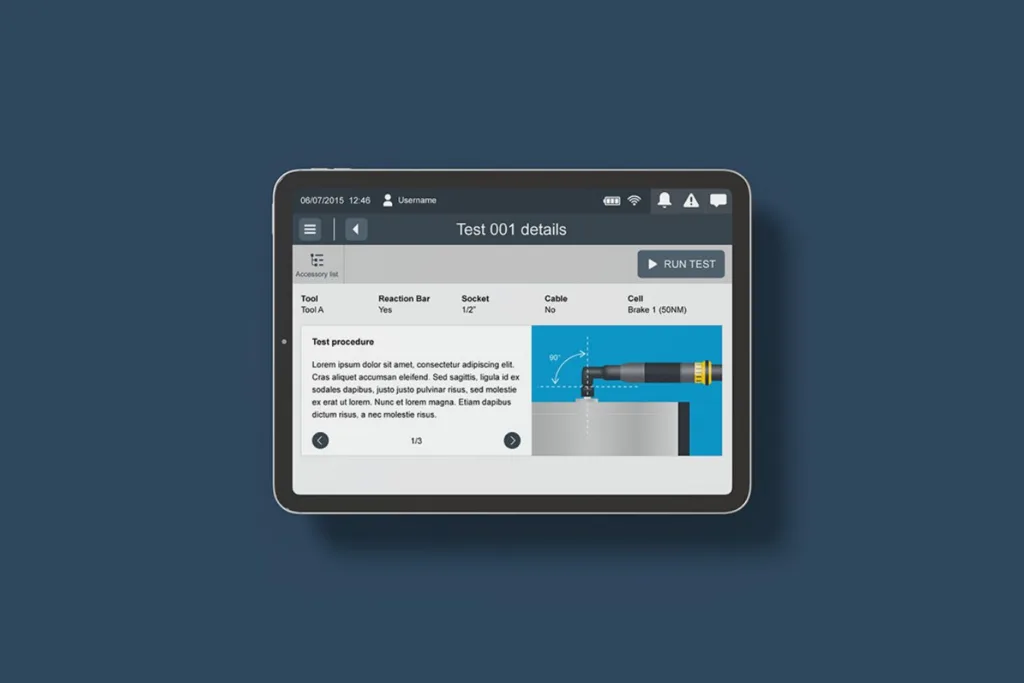

Interaction with the field

In line with Intré’s tradition, the Accessorize3D application is characterized by its strong interaction with the field.

Once the prototype has been shared with the client via the web or through a PDF file, the 3D model is exported for concrete processing with production machines.

Thanks to the long-standing collaboration with Tullio Giusi spa, a company that manufactures machines for button production, Accessorize3D is capable of exporting data directly compatible with Multimaker, GiusILaser, Profila, and Reader, enabling the immediate creation of a physical prototype without further steps.

In other words, the design station on which Accessorize3D operates is at the heart of a system that also includes the production machines with which it actively interacts.

This is where Intré showcases its best capabilities: connecting machines and enabling them to interact is our expertise.

How we worked

The Accessorize3D project was born in response to the widespread need in the button market to reduce the time and costs dedicated to prototyping.

On one hand, the designer, who is working under the tight deadlines of the collection, needs to quickly design and obtain the right button for the garment. On the other hand, the button manufacturer aims to compress the time spent on prototyping, as it involves halting production activities and sourcing the necessary materials, with no guarantee that the product will eventually be purchased.

The Accessorize3D project thus involved end clients, button manufacturers, and machine builders with the goal of creating a product that would truly fit into this industrial process.

The development was carried out through successive iterations: after an initial graphic study to evaluate the user experience, we created several versions, each time adding a new graphic object or a new process, which were submitted for approval by the stakeholders.

The development team consisted of a designer and four developers with different skill sets: some focused on the 3D graphic engine, while others concentrated on the final application.